PIVOT EM

Pivot Electric Machines Corp builds new and retrofits existing heavy equipment with economically viable and operational effective “next generation” battery systems.

PIVOT EM

Pivot Electric Machines Corp builds new and retrofits existing heavy equipment witheconomically viable and operational effective “next generation” battery systems.

OUR MISSION

Lithium-ion battery production is a dirty, high carbon emission process

The average battery powered automobile must be driven 150,000 km on clean power before its production cost is carbon neutral with an internal combustion engine (gas) vehicle.

We are dedicated to economically transforming the mining and construction industries into carbon neutral businesses that not only supply the green economy but are aligned with the social climate and economic imperatives of our changing world.

STATUS QUO

Go Green

Mining and construction industries are building the foundation for the green revolution but they are not green themselves.

The Tech

Existing manufacturers are invested in existing Lithium-ion battery technology.

Competition

High energy demands exceed the capacity of current battery energy density and charging capabilities so existing battery electric equipment is not competitive, except in extreme conditions.

Shift Focus

Major OEMs focus on new equipment sales, and do not prioritize a need for existing fleet conversion from diesel engines to battery power and under-estimate the market for competitive equipment in the mining and construction business.

ELECTRIC EQUIPMENT PARADOX

Production of Lithium-ion batteries is inherently carbon intensive and mining is a key component of producing battery metals

Existing battery technology is not efficient, robust or safe enough to effectively replace diesel engines that gobble up diesel at 4 liters/minute.

Mobile equipment accounts for 30% of carbon emissions in mines, more when you add ventilation and air heating.

Next generation batteries and chargers will provide a fast charging, robust, safe and economic solution.

Miners are racing to reduce carbon emissions to maintain social license.

OPPORTUNITY

The Decline

Existing Equipment manufacturers are tied to dead-end battery technology.

Carbon Neutral

Solid State batteries are the pivot that the mining and construction industry needs to move forward to a carbon neutral future.

Go Green

Mining and construction companies are under pressure to retrofit existing fleets and go green in new fleet purchases.

New Sales

Existing manufacturers ignoring retrofitting current equipment to electric and are focusing on new equipment sales.

The Market

Pivot’s initial focus is the Remanufacturing market, which is worth > $100b, and a long-term recurring heavy equipment market of $20b per year.

Long-Term

Pivot EM’s long-term plan is to manufacture OEM heavy equipment through relationships with remanufactured equipment customers.

EXECUTION TIMELINE

To Date

2013

First generation Electric equipment deployed underground

2017

Macassa Mine becomes the first all-electric mine

Sep 2021

Pivot Electric Machine (PEM) founded

Feb 2022

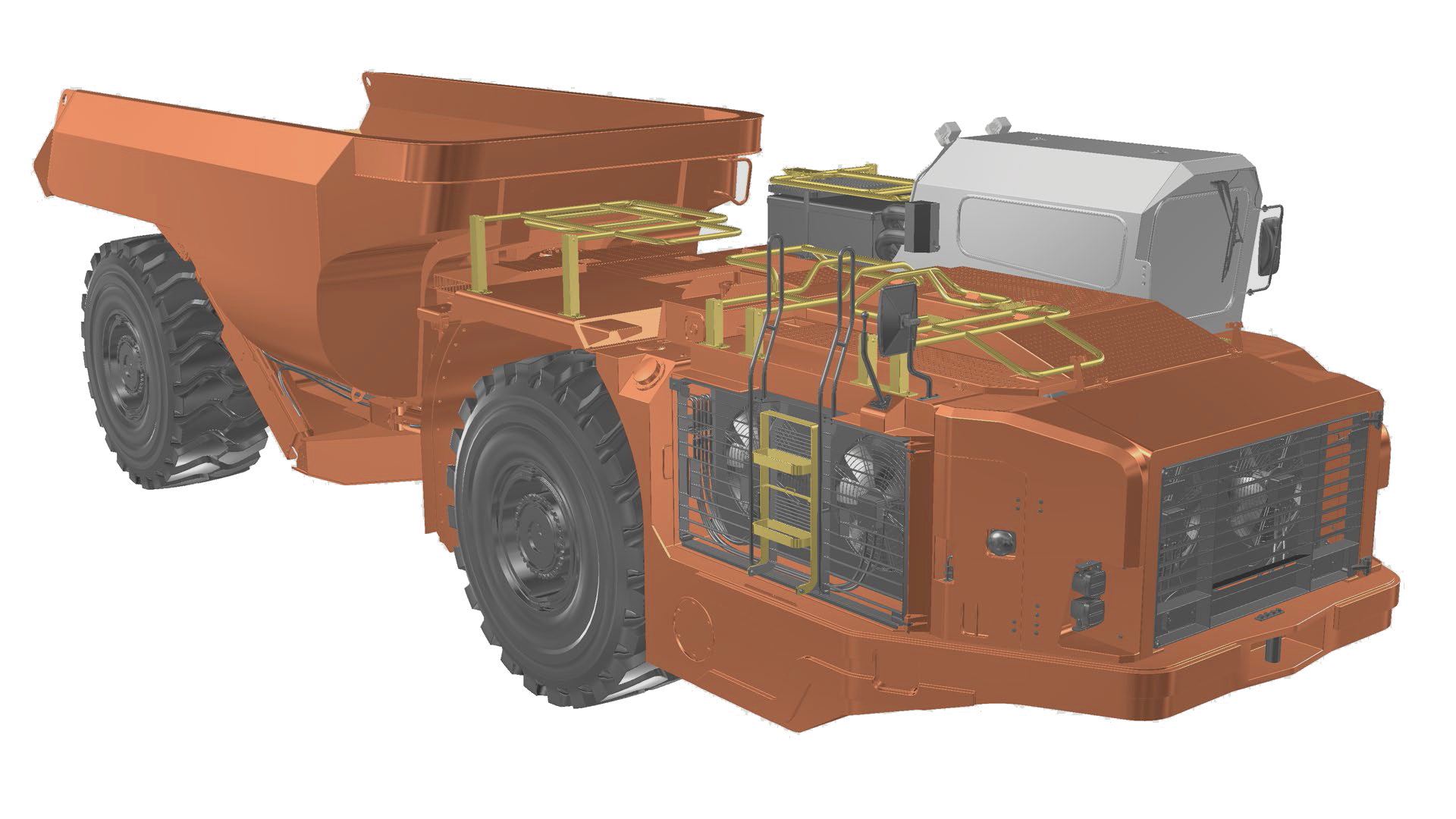

PEM chooses 30-80t battery/motor class for first design and produces conceptual battery

Apr 2022

PEM reserves B0 series batteries for prototype units

May 2022

PEM locks in high level conceptual design of 42t underground truck as first retrofit model for solid state batteries

Oct 2022

PEM begins discussions with multinational miner on economic model for converting 231t haul trucks

The Future

Q2 2025

Start build of converted 231t truck

Q4 2025

Start design of 363t haul truck conversion project

Q2-3 2026

Deploy and demonstrate commercial viability of BEV 231t haul truck

Q3-4 2026

Sign first commercial contracts and start fabrication for BEV 231t haul truck conversions

Q4 2027

Deploy and demonstrate commercial viability of BEV 363t haul truck